Ready...Set...Build! (psst, change my contents or click the "X" to delete me!)

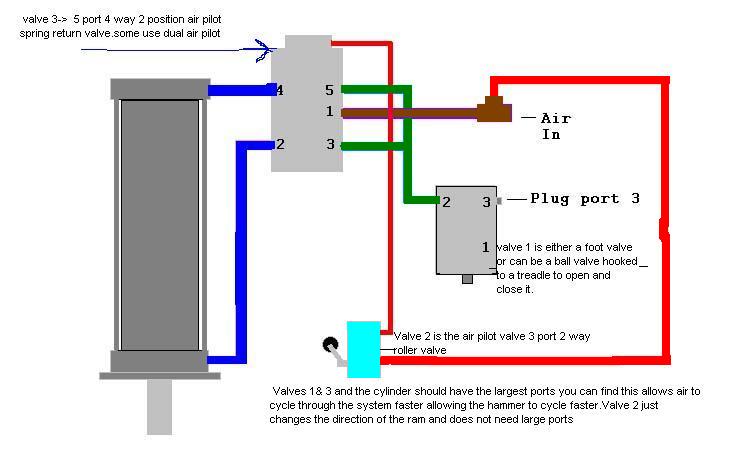

This page I of the air hammers I have and built. One is full size and the other is half the size. The full size hammer has a set of wheels that I can bolt on and a tongue so it can be towed like a trailer. If you go to the web site of Larry Zoeller he has down loadable plans for this small hammer. I have the air supply diagram on this page. this hammer has a small foot print and is a 30lb ram. The original plans call for a 1.5" bore air cylinder with a 10" stroke but I went with a 2" bore diameter with a 12" stroke. This allows for much better control of the ram itself and how hard or light that it hits and if set up right prevents the cylinder from topping or bottoming out. It should be noted that all cylinders and valves have the highest CV value you can get. ( Big Ports) The faster you can cycle air through this system the better the hammer works. The original plans called for the use of

brass for the guides for the ram. I went with UHMW plastic. This product was designed for this type of application. It has a low friction coefficient and is abrasion resistant. I still have the original on my hammer that were put on all those years ago (about 20) when I built my hammer. One of the other things I do is to keep many spare parts on hand so that if things break down they can be changed out quickly without having to wait for parts to come in.